Design stainless steel tanks

Stainless steel tank: Technology & project

Stainless steel integral accessories (valves, level indicators and wine tasting taps as standard)

» Sheet-steel in top quality AISI 304 and 316 Stainless Steel

» Monobloc integral construction

» Digitally controlled TIG welding to ensure sturdiness and total reliability

» All tanks with a capacity of up to 2000 litres have a front door created on the wall of the tank without weldin the frame

» Marble finish: attractive and practical

» Specific design for any condition of use

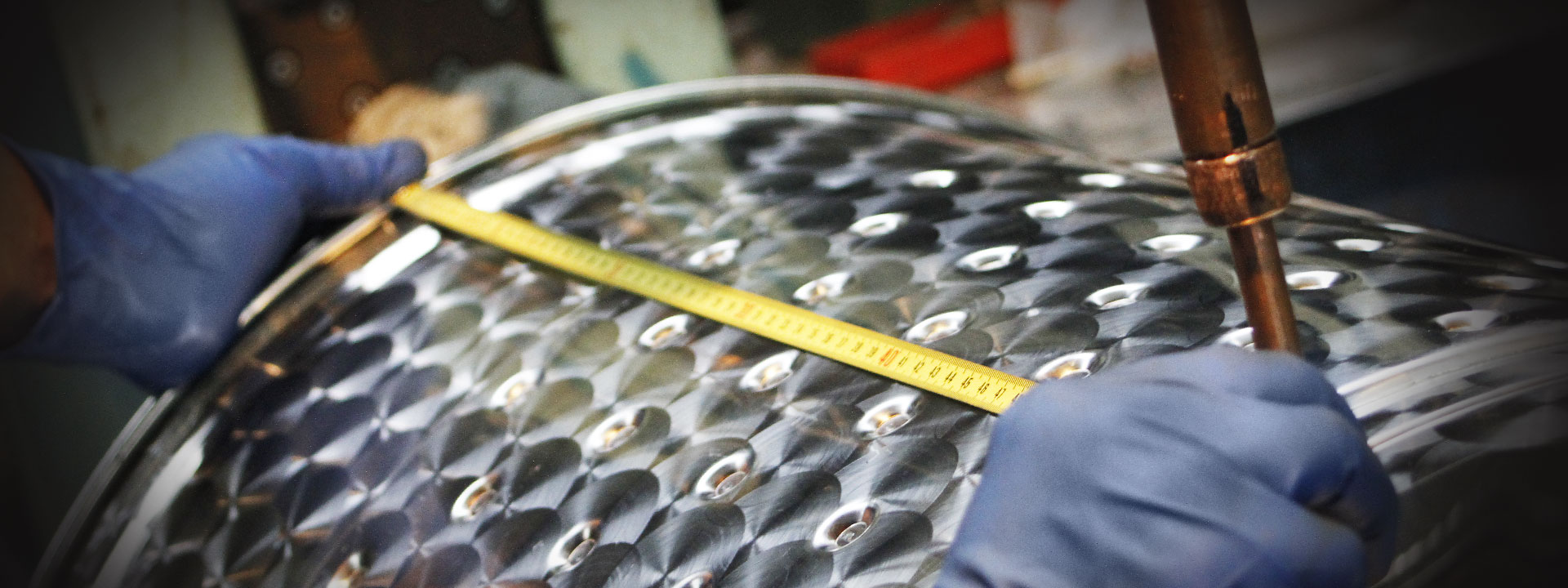

» Pre-pressed high-performance thermal exchange band. This technology of construction ensures the best thermal exchange efficiency and is particularly money-saving, in that it does not require powerful refrigerators. It also cuts down on unnecessary insulation and prevent the loss of exchange efficiency which may occur over time as a consequence of deposit inside the band.

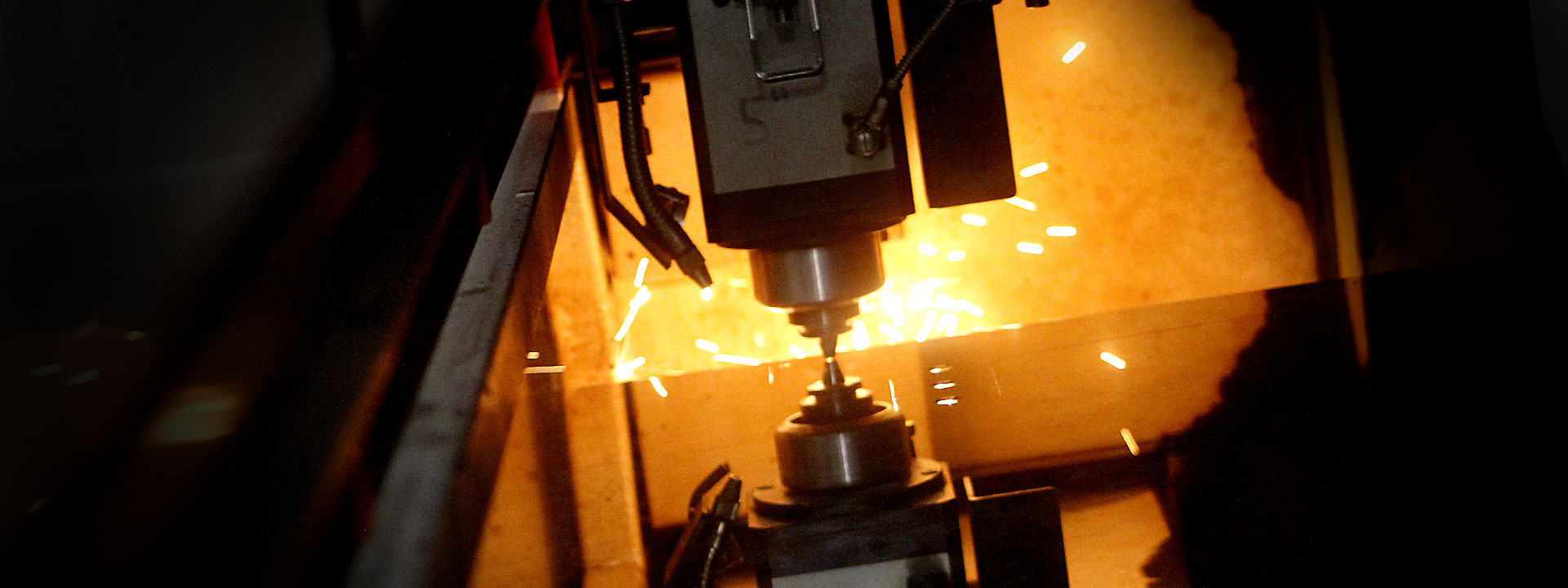

STAINLESS TIG WELDING (Tungsten Inert Gas)

TIG (Tungsten Inert gas) welding is a technically and aesthetically excellent welding system devised in California. By means of a torch which features a tungsten electrode, the tig welding adds no material to thin and medium thickness, but simply joints the two edges. The inert gas, added during the welding phase, excludes oxygen which could otherwise alter the molecular structure of the steel and make it susceptible to the liquids placed in the container. Welding wire in AISI 316 is used in case of greater sheet-steel thickness. Constant digital control always guarantees maximum welding precision.