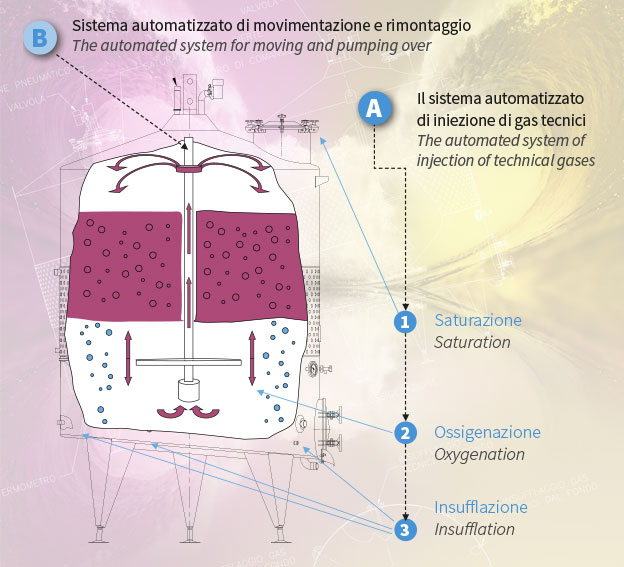

1. MULTIFUNCTIONALITY Onda® can be used for most types of wine, and at all stages of the winemaking process: pre and post-fermentation maceration, alcoholic and malolactic fermentation, aging on the fine lees and long term storage. 2. VERSATILITY It adapts easily to winemaking protocols in use and simplifies operations or issues normally complex: pumping over, oxygenation, stop or slow down of fermentation, put in suspension of the fine lees, correction of sulphidric smell, saturation of the tank with inert gas etc. 3. EFFECTIVE AND GENTLE EXTRACTION the automated moving and pumping over system which acts above and below of the “cap of grapes” and not directly on it, this maximizes the extraction of phenolic compounds while reducing the production of lees.

4. EASY CLEANING Onda® is free of interspace and all internal components are equipped with a system of rapid disassembly and washing which reduces the time of racking, cleaning and sanitization of the tank. 5. THE POSSIBILITY OF WINE MAKING WITHOUT ADDED SULPHITES Thanks to the pumping over without the use of pumps and to the injection system of technical gas, it’s attained inside Onda® a modified and controlled atmosphere that allowed the production of wine without sulfites or other allergens both on experimental scale and a production one*. Onda is a wine fermentation tank for produced also organic wine, natural wine without sulfites. 6. SAVINGS greatly reduces the labor costs because it works without the aid of pumps and their pipework that require specialized personnel both for their operation and for their cleaning. Onda® is completely automated: a single operator, with an intuitive control panel, can plan and manage the entire process of wine making and storage, even for several tanks simultaneously. * Employing Onda® and adopting appropriate hygiene measures, wine-making suitable equipment and a specific protocol it was demonstrated the possibility to make wine without adding sulfites and other allergens, it is recommended, however, that procedures are recommended and approved by an expert winemaker who is responsible for the quality of the final product.

Saturation from above for aging and long-term storage in a protected atmosphere.

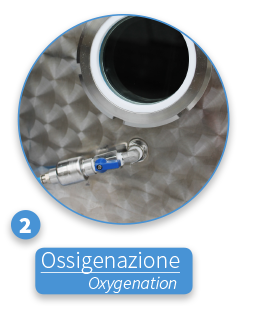

Oxygenation in the middle zone through the integrated porous plug

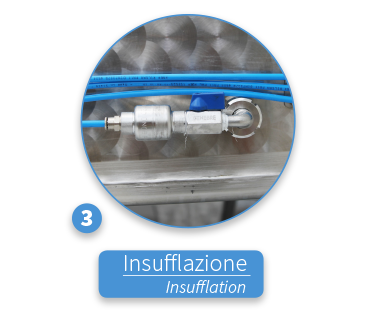

Insufflation from below with inert gas, to gently mix the must/wine or bring in suspension the fine lees during aging, or by compressed air for the macro-oxygenation of the product.

The aim of this competition is to enhance and promote the creations by manufacturers of equipment, products and services showing product and process innovations that may lead to technical progress in the fields of enology.

The award committee is composed of national and international leading figures in the world of enology, representatives of the scientific community and wine-makers associated to Unione Italiana Vini.

January 2016 – Wines & Vines

December 2015 – La Vigne

17 September 2015 – SIMEI – World leader in wine technology exhibition

July 2015 – EXPO 2015 – REGIONE TOSCANA – Le Aziende Eccellenti

29 July 2015 – PORTHOS – Indipendenti da sempre, ci occupiamo di vino, cibo e cultura

December 2012 – D.A. La rivista per superare le barriere culturali

November 2012 – Premio all’innovazione viticola ed enologica- Simei 2011

24 February 2012 – Civiltà del bere

10 October 2011 – Il Corriere Vinicolo n. 40